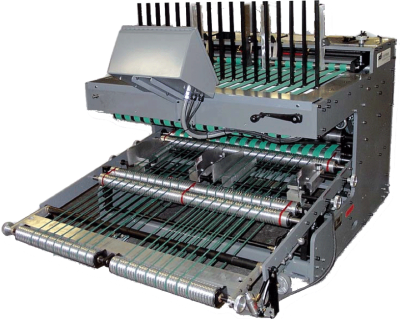

The Systems Technology Inc. Model 127F Stak-O-Veyor was designed to meet the needs of a variety of commercial printers in half web, combination folder, and in-line finishing applications. The unit easily changes over to one or two streams and can be used with bump turns to handle a multitude of products in a variety of space-saving layouts.

Product is jogged, crushed, and turned around a 16” diameter drum to produce tight stacks at waist high level while minimizing cracking, marking, and gusseting. The stacker can be unloaded from both sides or the rear, and features simple no-tool adjustments, air jets to assist stacking, and a manually-activated waste divert gate.

Benefits

- Built to increase productivity and profits

- Handles product configurations outside the normal combination folder type products such as single sheets and various in-line finished products depending on speed, paper weight, stream quality and other factors

- Produces higher stacks for less handling

- Stacks most products delivered by in-line finishing system as well as single and double delivery combination folders

- Reduces manpower

- Controls waste

- Fast set-up; on-the-fly running adjustments

Featured Benefits

- Waste divert gate

- Self-contained drive package

- Air jet stack assist

- Large turning drum

- Independent jogger drive with constant speed motor

- Independently adjustable joggers

- Optional Count Marking system

- Optional Press Speed Following System

- All controls on electrical panel for easy operation

- Mounted on casters for easy positioning

- More drum belts to carry minimum size product most effectively

- Stream shifting to align product with joggers and crusher roller

Stak-O-Veyor 127FW

The Systems Technology Inc. Model 127FW Stak-O-Veyor was designed to meet the needs of a variety of commercial printers in half web, combination folder, cover production systems and in-line finishing applications. The standard unit easily changes over to one or two streams. Multiple streams are available. Product is jogged, crushed, and turned around a 16 inch diameter drum to produce tight stacks at waist high level while minimizing cracking, marking, and gusseting. The stacker can be unloaded from both sides or rear, and features simple no-tool adjustments, air jets to assist stacking, and a manually-activated waste divert gate.

Benefits

- Stacks most products delivered by in-line finishing systems, as well as single and double delivery combination folders

- Reduces manpower

- Controls waste

- Handles product configurations outside the normal combination folder type products such as single sheets and various in-line finished products depending on speed, paper weight, stream quality and other factors

- Successfully stacks a wide range of in-line finished plow folded, perfed, with multiple around delivery

- Produces higher stacks for less handling

Featured Benefits

- Waste divert gate

- Self-contained drive package

- Air jet stack assist

- Large turning drum

- Independent jogger drive with constant speed motor

- Independently adjustable joggers

- Optional Count Marking system

- Optional Press Speed Following System

- Fast set-up; on-the-fly running adjustments

- All controls on electrical panel for easy operation

- Mounted on casters for easy positioning

- More drum belts to carry minimum size product most effectively

- Stream shifting to align product with joggers and crusher roller