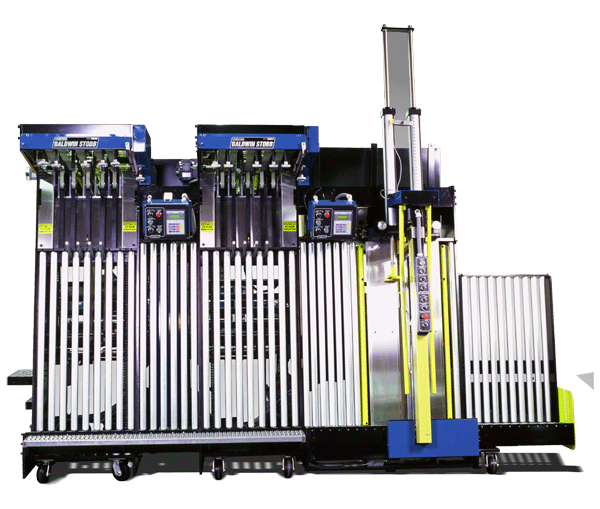

Both endboard inserters are located to the side of the stacking area. Each endboard magazine is capable of holding (60) 3/8-inch thick boards. The stacking fingers enter the stacking zone from the rear. Once the stack is started, there is no “pass off” and the entire log is deposited on the lower end board without disruption. Patented controls assure the highest stack quality.

The bundle transfer mechanism fully contains the bundle on all sides and is capable of queuing a bundle between the strapping and stacking area. The strapped-bundle transfer rollers move bundles into the tilt module.

The strapping head can be supplied with polypropylene or polyester, depending on customer requirements. A tilt module is included in the system and pivots the bundle from vertical to horizontal. Many options and design variations are available for this module depending on application and pressroom requirements. The AC drive systems are simple, reliable and do not require servo motors or other sophisticated controls.

- Automation allows one operator to be responsible for multiple stackers

- Independent stacking tables allow for faster cycle rates

- Operator controls & electrical control cabinets are mounted to the Model 195A, making it truly portable

- Portability = Less conveyor equipment = Less floor space = Reduced costs

- Accommodates a broad range of product format, page count and stock weight

- Quicker installation, start up and make-ready times

- Simple controls make training faster

- Available in high or low inlet heights

- Patented stacking table descent control means high quality stacks from top-to-bottom