The system automatically compensates for variations in shingle overlap, thickness and speed, with virtually no user intervention. It is intended for applications where exact count is crucial to the operations, such as in in-line finishing, mail sortation, pressroom stacker needs, and bindery lines.

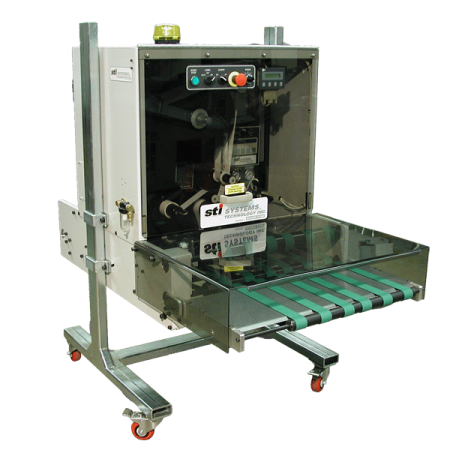

A shingled stream of products enters the system and passes under a high-speed laser sensor which enables highly accurate counting of the product. A specialized label applicator then precisely applies the peel-off label onto the leading edge of the product which corresponds to the desired pre-set count. The shingled stream is securely trapped between upper and lower belts that automatically adjust for the shingle thickness. The product stream exits the system with the labels securely attached, for further processing by a stacker or other downstream sortation processes.

The label can either be easily removed by the operator or it can be removed at any time in the future without any ink transfer or damage to the product. The label can be optionally printed with any customized marketing logo or message based on customer requirements.

Featured Benefits:

- Reduces costs by eliminating unnecessary overruns

- Up to 50% reduction in manning by eliminating manual weighing or counting in typical stacking operations

- Verified accurate counts build confidence in your customers

- Accurate count bundles greatly improve overall pallet integrity

- Elimination of costly secondary counting & batching operations off-line

- Small batch counts now attainable on-line at significant savings

- Mail sortation applications capability eliminate mail sort costs

- Simple, reliable design, easy to install, operate, move and maintain

- Small footprint- allows easy integration into any existing line

- Custom multi-stream versions available

- Total lock casters allow easy transport from one line to another

- Top registration of stream automatically accommodates varying stream thickness without any changeover

- Closed-loop control system ensures repeatable label placement, regardless of variations in shingle spacing or speed

- Wide range of infeed/exit heights and angles easily adapt to any line