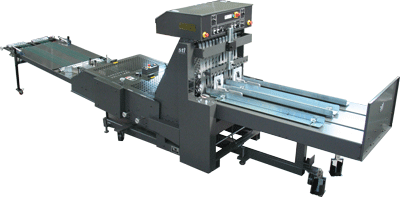

The Systems Technology Inc. Model HSB-NC is designed to meet the stacking need of the heatset and non-heatset printer looking to reduce manning and improve quality without the complexity of compensating overstackers, and at a fraction of the price. Setup and changeover are accomplished quickly without the need for special tools or highly-trained personnel.

The improved drive train operates 0-80,000 I.P.H. with all controls & adjustments conveniently mounted. Trouble-free operation and maintenance was designed into this rugged versatile horizontal stacker. If you are looking for a simple reliable stacker requiring minimum manning, then the Model HSB-NC is the stacker for you.

Options & Accessories

- Count batching systems with prox or laser input marking pen, UV, or other output devices

- Custom conveyors & turns available for any pressroom layout

- Table top accumulation – 67″ standard, shorter or longer available

- Pneumatically actuated good/bad copy entrance gate

Featured Benefits

- Tabloid, standard, quarterfold, digest products 4 page to 128 page

- Horizontal stacking reduces manning — no rejogging required

- On-the-fly adjustments minimize setup and changeover time

- Patented vibrating belt joggers align even 4 page tabs

- Drumless low tension timing belt design reduces marking, gusseting & jam ups

- Heavy duty pneumatic crushers with emergency stop button

- Patented “Quick Belt Replacement” features reduced maintenance down time

- Stacks single sheets and multiple page products including unbalanced products

- Press speed following

- Stacker and conveyor end of run signature cleanout

Horizontal Brick Stacker Model HSB-NC-ILF-1 & HSB-NC-ILF-2

The Systems Technology Inc. Model HSB-NC-ILF-1 Single Stream Horizontal Brick Stacker is designed to provide in-line finishing printers with a simplified, cost-effective brick stacker that is easy to operate through a broad range of in-line finished products sizes, folds, shapes, and high speeds. The wider Model HSB-NC-ILF-2 provides the ability to handle dual product delivery streams from the rotary cutter.

The Model HSB-NC-ILF is tuned for the smaller sizes and higher piece production rates of the in-line finishing printer. The well-jogged stack and larger accumulating delivery table allow significant manning reductions as compared to hand-fly or drum-stack approaches. The simple setup and flexibility for a full range of inserts, signature, and “square-inch” direct mail work make this a real workhorse.