Web Offset Printer: Denver, Colorado

Context:

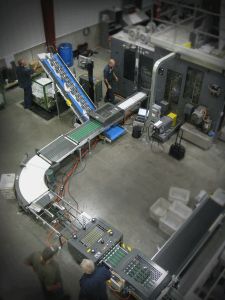

A large and well respected web offset printer recently purchased a new Goss Sunday 2000 web press to place in their recent building expansion. They decided to equip it with an automated horizontal stacker bundler they already had on-hand. These two machines were connected by a short length of signature conveyor, but space was still very tight. Realizing that their high speed press would function more efficiently with automated waste handling and automated good copy capture, this printer came to STI to design a system that would compactly fit into the tight space of the pressroom, interface with the automatic waste divert and improve the material handling of their horizontal stacker bundler.

Key Challenges:

- Limited Space

- Automated good copy divert

- Automated waste copy divert

- Signature conditioning to improve stacker bundler operation

- Minimal press down time during installation

Solution:

In order to achieve the objectives listed above, Systems Technology designed an automatic waste divert that interfaced with an existing weigh scale located in the floor. This helped to save space in the limited area available. In addition, stream conditioning was improved by adding signature stream joggers and a highly effective Belt Crusher Module to the line. Also, a good copy stream divert and slow down collection conveyor were provided to reduce waste in the event the existing stacker bundler experiences unexpected downtime. All of these modules were finally tied together with a custom STI control console. Since downtime to install the equipment needed to pose the least interruption to the new press’ operation, detailed project coordination with this printer’s personnel resulted in less than a day’s down time for the entire project.